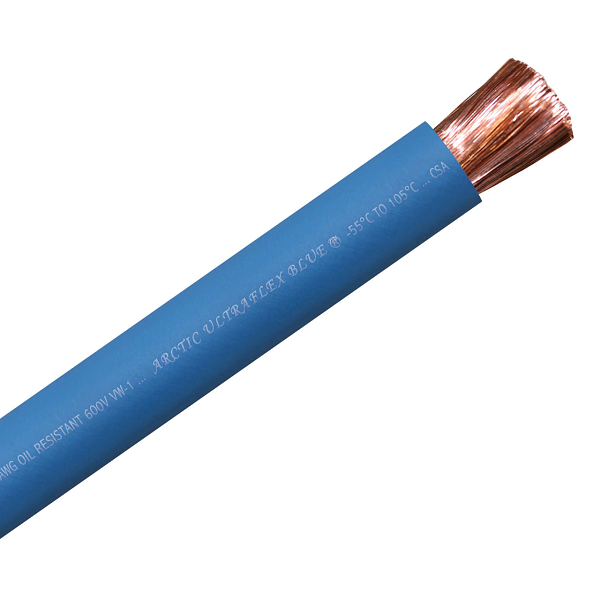

- Superior flexibility to -55°C (-67°F)

- Class K fine stranded copper construction

- Resists oil, grease, chemicals, abrasion

- Sunlight and weather resistant

- Flame retardant (VW-1)

- UL Recognized and CSA Approved

- Environmentally safe

- Made in the USA

- 4/0 AWG

- Class K Copper Stranding (2109/30)

- .530" Conductor Outside Diameter

- .085" Insulation Thickness

- .710" Finished Outside Diameter

- Ampacity at 30°C (86°F)*: 440A

- Ampacity at 40°C (104°F)*: 411A

- UL 508A Industrial control panels

- Internal appliance and equipment wiring

- Inverter cables and wiring

- Industrial machines and robotics

- Construction equipment

- Marine, RV and automotive wiring

- Medium and heavy-duty trucks and trailers

- Load banks, motor leads, welding cable

- Forklifts and golf carts

- Batteries and chargers

- Power hookup cable

| Insulation Properties | Test Method | Performance |

|---|---|---|

| Specific Gravity (±.02) | ASTM D-792 | 1.30 |

| Durometer Shore 'A' (±.02) INST./15 seconds |

ASTM D-2240 | 77/65 |

| Tensile Strength (60 mil) | ASTM D-412 | 2000 |

| Elongation % | ASTM D-412 | 300 |

| Brittle Point (C) | ASTM D-746 | -55°C |

| Oxygen Index % | ASTM D-2863 | 25.0 |

| Oil Aged 18 Hours @ 121°C % Retention of Tensiles % Retention of Elongation |

UL Standard UL Standard |

129% 72% |

| Air Aged 7 Days @ 136°C % Retention of Tensiles % Retention of Elongation |

ASTM D412-80 ASTM D412-80 |

109% 100% |

| Oil Aged 7 Days @ 60°C % Retention of Tensiles % Retention of Elongation |

ASTM D412-80 ASTM D412-80 |

124% 89% |

| VW-1 Flame Test | UL Standard | Pass |

| Product Cold Bend Test | UL Standard | Pass |

| Voltage Rating | UL Standard | 600 |

*Ampacities of 600V and 1000V 105°C AWM wires in air. Ampacities based on single conductor in free air, 30°C or 40°C ambient temperature as specified, 105°C conductor temperature, per NEC table 310-17 (adjusted for 105°C). Free air ratings assume a one-cable-diameter space between adjacent conductors.